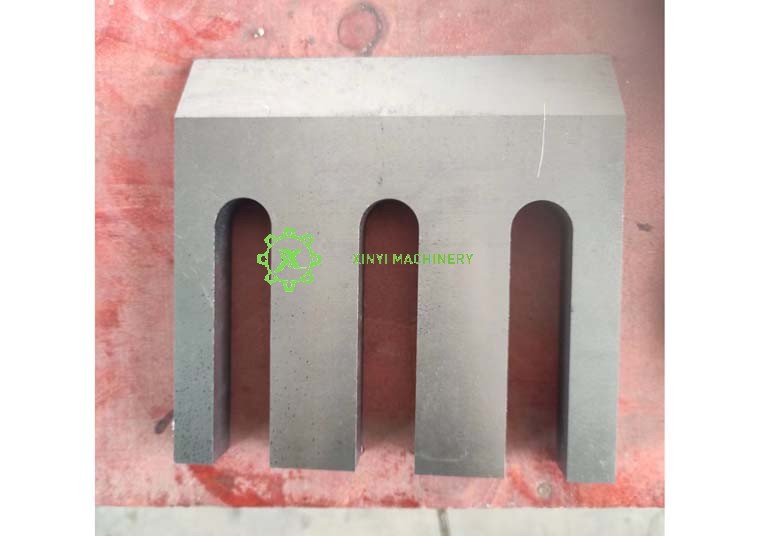

Crusher blades/knives are one of the key parts of crushers, which is responsible for cutting the material into small pieces. As the blade will receive material wear and corrosion in high-speed operation, so regular sharpening is necessary.

The frequency of blade/knife sharpening is different for each customer due to different crushed materials, different hourly output, different size and dimensions of crushed materials, and different models of crushers. When the blade/knife is not sharp, or when the current of the crusher rises, it is necessary to sharpen the blade/knife.

Of course, the blade/knife to choose a better material, higher hardness, will greatly reduce the frequency of grinding, improve the service life of the blade. Good crusher blade/knife materials are Alloy steel, 9CrSi, SKD11, D2, etc.

Actionable Signs It's Time to Sharpen

Monitoring these operational signs is more effective than just tracking hours:

1. Decreased Production Output: The most common sign. The machine takes longer to process the same amount of material.

2. Increased Power Consumption: The motor draws more amps (visible on the ammeter) as it works harder to force material through dull blades.

3. Poor Product Quality: The output becomes larger, uneven, stringy, or has a "wooly" appearance (especially in plastics) instead of cleanly cut granules.

4. Excessive Noise and Vibration: Dull blades crush and tear material instead of cutting it, generating more heat, friction, and noise.

5. Material Not Feeding Properly: The rotor can't grab and pull material into the cutting chamber effectively, causing it to "bounce" in the hopper.

Best Practice Recommendation

· Keep a Logbook: Track hours of operation, materials processed, and when sharpening was performed. This data will help you predict future maintenance needs accurately.

· Invest in a Spare Set: For operations where downtime is costly, having a pre-sharpened and balanced set of blades ready to swap in is the most efficient strategy.

· Professional Sharpening & Balancing: Always have sharpening done by a professional service. They ensure the correct edge angle and, most importantly, dynamically balance the entire rotor after blades are installed. An unbalanced rotor causes violent vibrations that will destroy bearings and damage the machine.

In conclusion, the frequency is variable and driven by material abrasiveness, desired output, and blade quality. By selecting the right blade material (like the excellent examples: Alloy Steel, 9CrSi, SKD11, D2) and monitoring machine performance for the signs of being dull, operators can optimize their maintenance schedule for maximum efficiency and cost-effectiveness.