Here is a comprehensive guide on how to select the right single-shaft shredder blades, broken down into key factors.

Understanding the Basics: Blade Types & Mounting

First, it's crucial to understand the two main components of a shredder's cutting system:

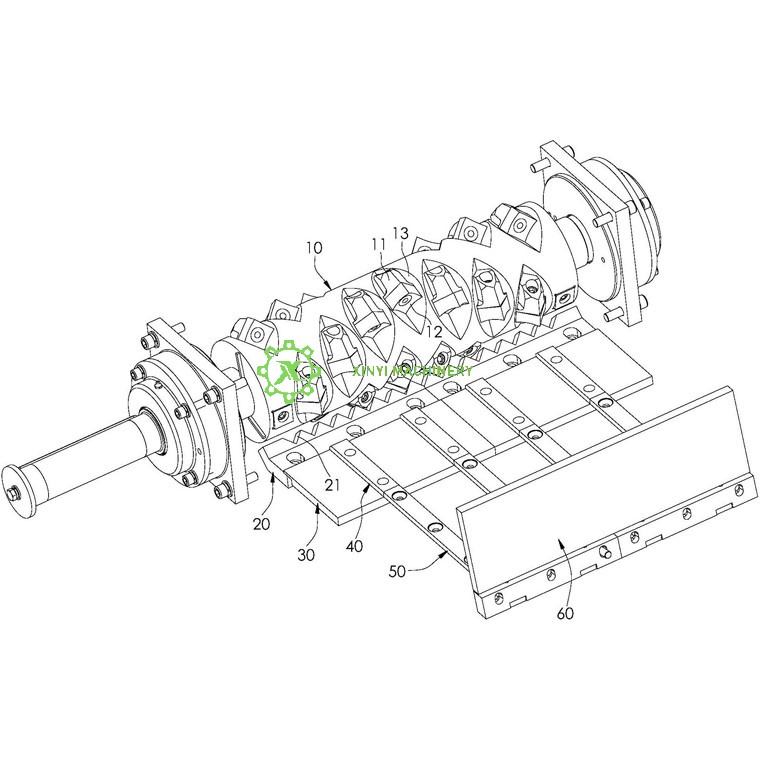

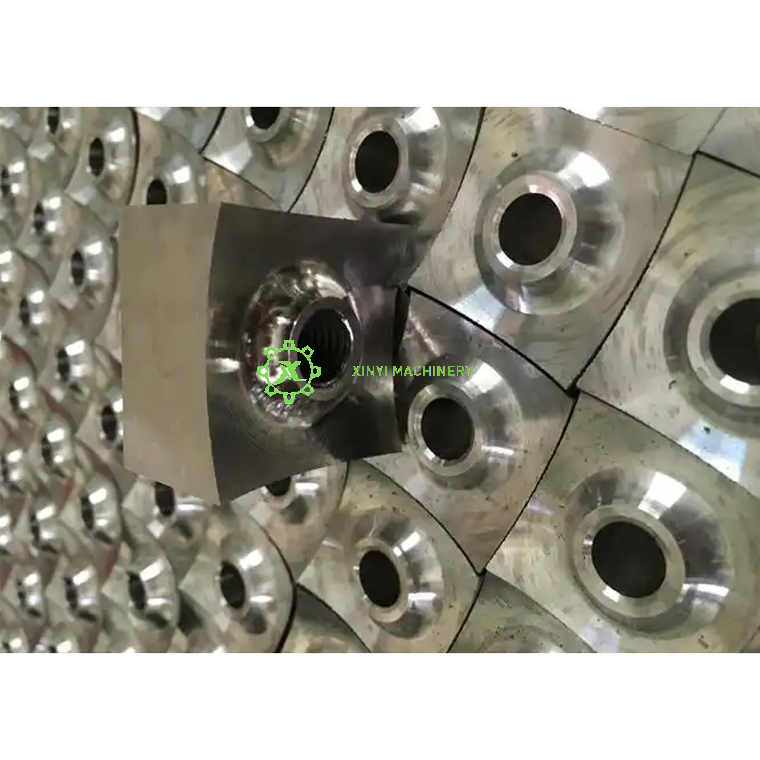

1. Rotor Blades (or "Hooks"): These are the primary, movable blades mounted directly onto the rotating shaft (rotor). They do the majority of the cutting and tearing.

2. Bed Blades (or "Counter Knives"): These are stationary blades fixed to the shredder's housing. The rotor blades pass very close to the bed blades, creating a scissor-like shearing action.

The selection process involves choosing the right material, geometry (shape), and configuration for both sets of blades.

Key Factors to Consider When Selecting Blades

1. Material to be Shredded (The MOST Important Factor)

The composition, size, hardness, and abrasiveness of your feedstock dictate everything.

· Plastics (e.g., lumps, purgings, pipes, film):

o Tough & Ductile (e.g., PE, PP, PET lumps): Require blades with a sharp, acute angle for a clean shear cut. Blades must be very hard to resist deformation.

o Abrasive (e.g., fiberglass-reinforced plastics, filled materials): The priority is wear resistance, not necessarily sharpness. Blades made from highly wear-resistant materials (like tool steel with high chromium content) are essential, even if they require more frequent sharpening.

o Soft & Stringy (e.g., film, fibers, textiles): Require sharp blades optimized for slicing and tearing rather than pure shearing. A different hook geometry helps prevent wrapping.

· Wood (e.g., pallets, construction waste, logs):

o Blades need to be tough to handle potential nails and dirt (contaminants). They often have a more robust, durable design and are made from steels that balance hardness with toughness to avoid chipping.

· Metals (e.g., light aluminum extrusions, non-ferrous turnings):

o Requires extremely hard and tough blades to handle the high shear forces. Often use specialized, heavy-duty alloys.

· E-Waste (WEEE):

o Highly abrasive and mixed. You encounter hard plastics, circuit boards (fiberglass), and some metals. Maximum wear resistance is key.

· Paper & Cardboard:

o Less abrasive but can quickly dull blades if processed in high volumes. A standard sharp blade is sufficient, but corrosion resistance might be a factor.

2. Blade Material & Hardness

The steel alloy and its heat treatment (hardness) determine durability.

· Tool Steel (e.g., D2, H13, 1.2379): The most common choice. Offers an excellent balance of hardness (typically 58-62 HRC) and toughness. Good for most plastics, wood, and general-purpose shredding.

· High-Speed Steel (HSS): More expensive but offers superior red-hardness (stays hard at high temperatures) and wear resistance. Excellent for abrasive materials and high-throughput operations.

· Tungsten Carbide Tipped (TCT) or Overlays: The premium choice for extreme abrasion. A layer of ultra-hard tungsten carbide is welded onto the cutting edge of a tough steel body. This is the go-to solution for the most abrasive materials like fiberglass, carbon fiber, and minerals. Lifespan can be 10x that of standard tool steel.

· Stainless Steel: Used primarily in food-grade or corrosive environments where contamination and rust must be avoided.

3. Blade Geometry (Shape/Design)

The shape of the "hook" on the rotor blade defines how it engages with the material.

· Shear Cut Blades: Have a sharp, acute angle. Designed for a clean, scissor-like cut against the bed knife. Best for hard, brittle plastics and precise size reduction.

· Rip-Tear Blades: Have a more square or obtuse angle. Designed to grab, tear, and rip apart materials. Better for tough, stringy, or ductile materials that might otherwise wrap (e.g., film, textiles, tires).

· Multi-Sided Blades: Many industrial blades are designed to be reversible (double-sided) or even indexable (multiple edges), allowing you to use different sharp edges before the blade needs to be replaced or fully re-sharpened. This extends service life and reduces downtime.

4. Blade Configuration on the Rotor

How the blades are arranged on the shaft affects the shredding size and efficiency.

· Helical Design: Blades are staggered in a spiral pattern around the rotor. This creates a continuous, progressive cut, reducing shock load on the motor and drive train, leading to smoother operation and lower energy consumption. This is the most common and efficient design.

· Straight Design: Blades are mounted in a straight line across the rotor. Can create a pulsating load as all blades engage at once. Less common in modern industrial shredders.

5. Operational Factors

· Desired Output Size: The clearance between the rotor blades and the bed blades, as well as the screen size, determines the final particle size. Closer tolerances are needed for finer grinding.

· Throughput Capacity: Higher volumes require more wear-resistant materials (HSS, TCT) to maintain performance over longer periods.

· Budget: There is always a trade-off between upfront cost and longevity. Standard tool steel is cheaper initially, while TCT blades have a much higher upfront cost but a significantly lower cost-per-ton in the long run for abrasive applications.

Step-by-Step Selection Process

1. Analyze Your Feedstock: Be specific. What is it? How hard/abrasive/tough/stringy is it? Are there contaminants?

2. Define Your Goal: What output size do you need? What is your target throughput?

3. Consult Your Shredder Manufacturer: This is the most important step. They know their machine's capabilities and can provide precise recommendations based on your specific material and goals. Provide them with a sample of your material if possible.

4. Choose the Material: Based on the abrasiveness, decide between Tool Steel, HSS, or TCT.

5. Choose the Geometry: Based on the material's behavior (brittle vs. ductile), decide between a shear or tear hook design.

6. Consider Operational Costs: Calculate the Total Cost of Ownership (TCO). A more expensive blade that lasts 5 times longer is cheaper in the long run.

Maintenance is Key

Selecting the right blade is only half the battle. Proper maintenance is crucial:

· Sharpening: Keep blades sharp. Dull blades increase power consumption, generate heat, and produce poor-quality flakes.

· Gap Adjustment: Maintain the correct gap between rotor and bed blades. A too-large gap will tear rather than cut, and a too-small gap will cause premature wear.

· Inspection: Regularly check for nicks, cracks, and wear.

Final Advice: Partner with a reputable shredder manufacturer or a specialized blade supplier. They are experts and can save you significant time, money, and downtime by helping you make the correct selection from the start. Never assume the standard blades that came with your machine are optimal for your unique material stream.