In the context of a plastic crusher, a mesh (also commonly called a screen, sieve, or grating) is a perforated metal sheet that acts as a filter and size-control mechanism. It is one of the most critical components determining the final size of the crushed plastic particles.

Here’s a detailed breakdown of what it is, its function, types, and importance.

1. Primary Function: Controlling Particle Size

The main job of the mesh is to ensure that only plastic particles smaller than a specific size can exit the crushing chamber.

· How it works: The rotating blades inside the crusher cut and shear the plastic against the stationary blades. This forces the small fragments against the inner surface of the surrounding mesh.

· The Filter: Particles that are small enough to pass through the holes in the mesh are ejected out of the machine (usually by a suction system or gravity).

· The Recycle: Particles that are too large to pass through the holes remain inside the crushing chamber to be cut again and again by the rotating blades until they are small enough to escape.

2. Key Characteristics of a Crusher Mesh

· Material: Typically made from hardened, high-carbon, or alloy steel to resist the extreme abrasion caused by constant friction with plastic fragments.

· Thickness: The thickness of the metal sheet affects its durability and longevity. Thicker meshes last longer but can be slightly less efficient for very fine grinding.

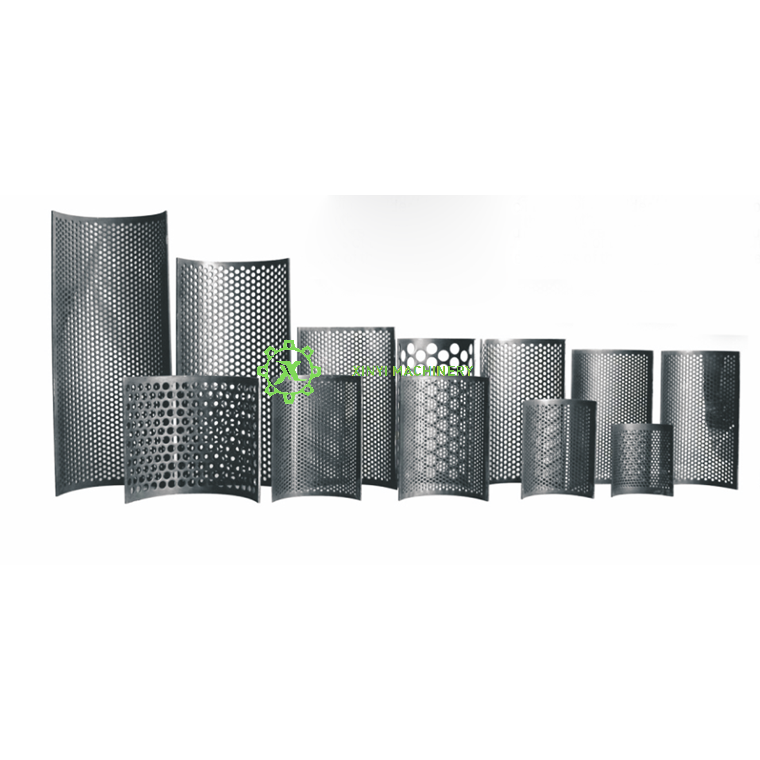

· Hole Perforation: This is the most defining feature. The holes can be:

o Round Holes: The most common type. They produce small, granular particles often called "regrind" or "flakes."

o Square Holes: Less common, produce slightly different shaped particles.

o Slots (Grating): Long, narrow holes. Often used for preliminary crushing or for materials that tend to string, as they are less prone to clogging.

3. Mesh Size and Measurement

· Millimeters (mm): The most straightforward measurement (e.g., an 8mm mesh has holes 8mm in diameter).

Choosing the right mesh size is critical and depends on the application:

· Large Mesh (e.g., 20-40mm): Used for coarse, initial size reduction.

· Medium Mesh (e.g.,10 -16mm): A common standard for general-purpose recycling to create regrind for reprocessing.

· Small/Fine Mesh (e.g., 6-8mm or smaller): Used to produce a fine powder, often for specific applications like rotational molding or creating high-quality recycled compounds.

4. Importance and Impact

· Product Quality Consistency: It ensures every batch of regrind is a uniform size, which is crucial for consistent processing and product quality when the regrind is mixed with virgin material.

· Machine Protection: Prevents large, uncut pieces from jamming or damaging the extrusion or injection molding machine that will use the regrind.

· Throughput Efficiency: The right mesh size balances particle size with production speed. A finer mesh will produce smaller particles but may slow down the overall output rate as it takes longer for material to pass through.

5. Maintenance: Clogging and Wear

The mesh is a wear item and requires maintenance:

· Clogging: Soft or hot plastics can melt and smear, clogging the holes. Some meshes have special anti-clogging coatings (like Teflon) or are designed to be easily removed and cleaned.

· Wear: Over time, the constant abrasion will wear down the edges of the holes, effectively making them larger. This leads to a gradual increase in particle size. Worn-out meshes must be replaced to maintain product consistency.

Summary :

A mesh in a plastic crusher is a replaceable screen with precisely sized holes that surrounds the cutting blades. Its sole purpose is to act as a filter, ensuring only plastic particles smaller than the hole size can exit the machine. It is the key component that controls the final particle size of the crushed plastic, making it essential for quality control in the recycling process.

XINYI MACHINERY is a China leading manufacturer of all kinds of plastic crushers and plastic crushers’ parts( including meshes of plastic crusher, blades of plastic crusher, etc.).