PLASTIC PELLETIZING MACHINE/ EXTRUDER MACHINE LINE (CUTTING UNDER WATER) XY07002

Product parameters

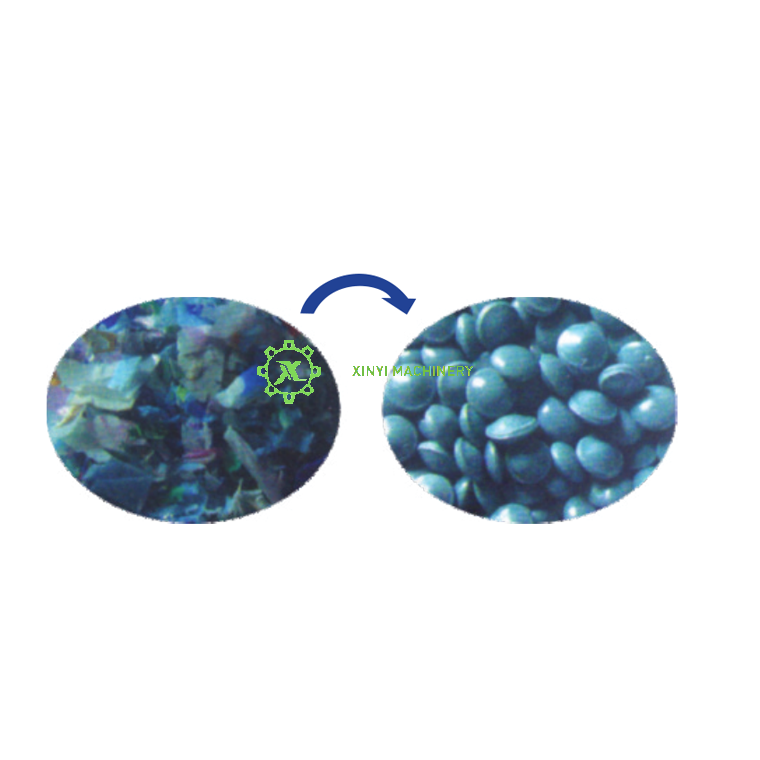

The straight-cutting and plastic extruder is mainly composed of double-level venting extruder, underwater cutting die, flexible cutter seat automatic vertical de-watering device, vibrating screen, air-feeding system, material collector. The traditional recycled plastic extruder always do cutting after extruding and curing the plastic strip, while the straight-cutting plastic extruder is a new type of machine cutting the granular underwater when the plastics in the melted state, which have obvious advantages against the solid cutting technology.

Main Features:

1. As the plastics is cooled and solidified after cutting in the melted state, no dust will be formed during cutting and the cuttings will have good quality with regular shape, better for packaging and transportation.

2.The output and cutting speed can be adjustable according to the volume of extrusion. To change the size of the cutting, manual adjustment of the number of knife holders can be used to change the size and shape of the cuttings.

3.The straight-cutting and underwater cutting process allows the molten plastics to be cut and cooled directly, so the water can be removed efficiently after high-speed dewatering process, proving a better drying effect. The subsequent process is equipped with the vibrating screen to cool down the granule. The impure granule will be removed automatically so the automation and easy operation can be achieved for the process.

Technical Parameter:

Item | Technical Parameters |

Suitable Material | LDPE, HDPE |

Cutting Motor Power | 2.2KW, speed can be adjusted. |

Number of cutter’s blade | 4 pcs, manual adjustment |