A well-chosen crusher is a reliable workhorse that maximizes your profit; a poorly chosen one leads to downtime, high costs, and inconsistent output.

1. Know Your Plastic Types and Form

This is the most critical step. The crusher's design, rotor type, and blade material are all determined by your feedstock.

· Material Hardness:

o Soft Plastics: PET bottles, HDPE jugs, LDPE film, PP containers. These require sharp, scissor-like blades for a clean cut.

o Hard/Brittle Plastics: ABS, PS, Acrylic, PC. These require hard, durable blades that can shatter the material without dulling quickly.

o Abrasive & Engineering Plastics: Materials with glass fiber (e.g., GF-Nylon) are extremely abrasive. They demand heavy-duty crushers with wear-resistant, carbide-tipped blades.

· Physical Form:

o Injection Sprue & Runners: Small, thick chunks. A small, open-throat beside-the-press granulator is ideal.

o Bottles & Containers: Bulky but thin-walled. They need a crusher with a large feed opening and special "ripper" blades to prevent spinning in the hopper.

o Pipes & Profiles: Long, continuous shapes. They require a crusher with a horizontal feed channel and a press-down ram.

o Films, Bags, & Fibers: Tangle-prone materials. They need a special slow-speed crusher with a forced feed system to prevent wrapping around the rotor.

2. Consider the Production Capacity (Throughput)

Match the crusher's capacity to your volume to avoid bottlenecks.

· Calculate Your Hourly Needs: Estimate the weight (in kg/hr or lbs/hr) of material you process. Choose a crusher whose rated capacity is 20-30% higher than your peak load to ensure smooth operation and allow for growth.

· Rotor Design: Larger, slower rotors provide more torque for thick materials. Smaller, faster rotors are better for high-volume, thin materials.

3. Evaluate the Size and Design of the Machine

The machine must fit your space and integrate with your material handling.

· Footprint: Measure your available floor space. Will it fit beside a molding machine or in your processing line?

· Hopper Design:

o Feed Opening Size: It must be large enough to accept your largest plastic parts without manual pre-breaking.

o Hopper Angle: A steep angle ensures parts slide down into the cutting chamber for automatic feeding.

· Discharge System: How does the crushed material exit?

o Gravity Fall: Into a bin or bag underneath. Simple but requires manual emptying.

o Blower System (Pneumatic Conveying): Blows the material through a pipe to a central storage silo. Essential for automation.

o Screw Conveyor: Moves material horizontally to another location.

4. Understand the Cutting Mechanism

This is the heart of the machine's performance.

· Rotor Design:

o Open Rotor (Scissor-Cut): Typically 3-5 knives. Best for clean, low-dust cutting of soft and hard plastics. Easier to maintain.

o Closed Rotor (Cascade Cut): Many small knives (12+). Excellent for high-volume shredding of thin-walled materials like bottles and films.

· Knife Configuration: Staggered rotor and bed knives create a shearing/scissoring action, which is more efficient and produces a cleaner cut than straight knives.

5. Power and Energy Consumption

A powerful motor ensures the crusher can handle tough jobs without jamming.

· Motor Power (kW/HP): Bigger, harder materials require more powerful motors. Do not underpower the machine.

· Energy Efficiency: Inquire about energy-efficient motors (e.g., IE3/IE4 standards). They reduce operating expenses over time.

6. Ease of Maintenance and Cleaning

Downtime is lost money. Choose a machine designed for quick service.

· Easy Access: Can you access the cutting chamber and screen easily? Look for hoppers that swing open or chambers that slide out.

· Quick-Knife Change System: Some models allow you to change or rotate knives without fully disassembling the rotor, saving hours of labor.

· Screen Change: The screen size determines the flake size. Ensure screens are easy to remove and replace.

7. Safety Features

Plastic crushers are powerful machines. Safety is non-negotiable.

· The machine must not start if the hopper is open or the safety gate is not closed.

· Emergency Stop Buttons: Prominently placed and easily accessible.

8. The Importance of Your Supplier (Manufacturer)

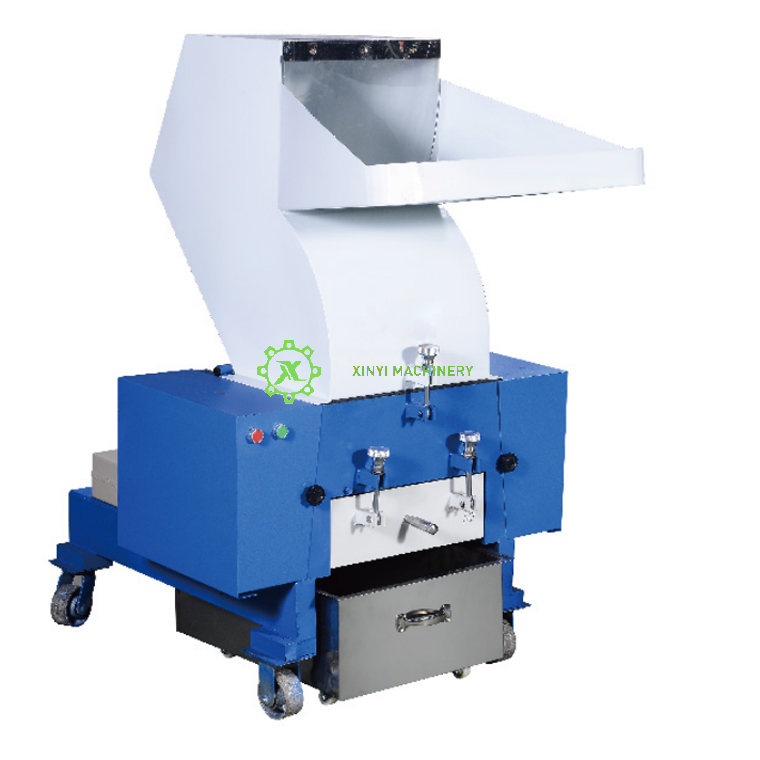

Your choice of manufacturer is as important as your choice of machine. This is where a company like XINYI MACHINERY demonstrates its value.

· Expertise & Product Range: As a leading manufacturer of crushers, shredders, and granulators, they can offer unbiased advice on the right type of machine (crusher vs. shredder) for your specific application.

· Customization: Leading manufacturers can often customize the hopper, discharge, blade type, and screen to your exact needs.

· Quality of Components: The durability of the blades, the strength of the rotor, and the quality of the steel used in the chamber directly impact the machine's lifespan and performance. A reputable manufacturer uses high-quality materials.

· After-Sales Support & Service:

o Availability of Spare Parts: Ensure blades, screens, and bearings are readily available.

o Technical Support: Do they offer installation, training, and troubleshooting support?

o Warranty: What is covered and for how long?

For a detailed discussion on which plastic crusher or shredder is right for your business, providing a sample for testing, or to explore their range of machines, contacting XINYI MACHINERY directly would be an excellent next step. Their expertise as a leading manufacturer can provide you with tailored solutions.