A Guide to Selecting Double Shaft Shredder Blades/Knives

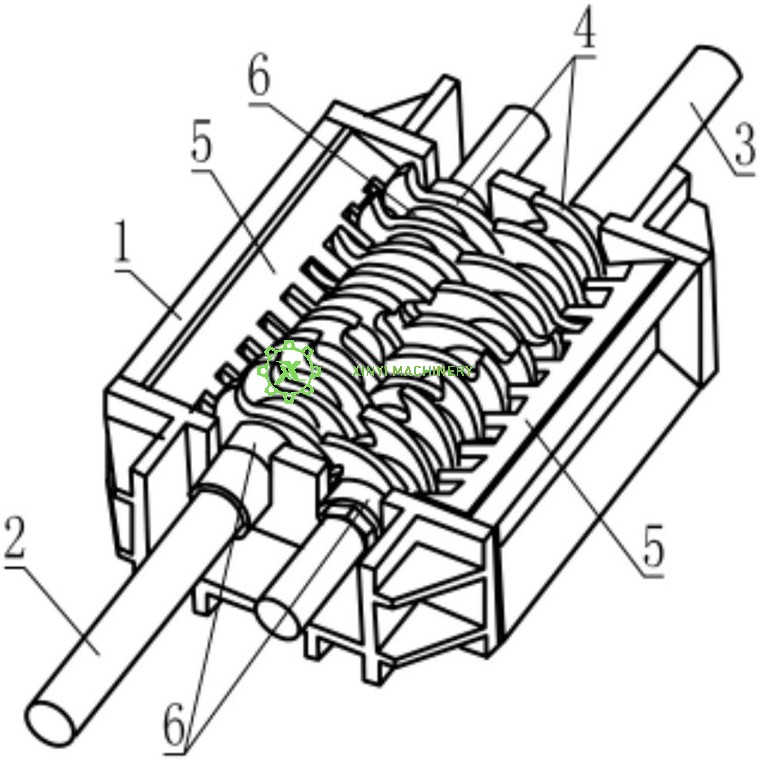

Selecting the correct blades for your double shaft shredder is the single most important factor in determining operational efficiency, product quality (particle size), and long-term cost-effectiveness. The right blade ensures high throughput, minimizes downtime for changes or sharpening, and reduces power consumption.

1. Matching Blades to Material Applications (As Provided)

Your provided chart is an excellent summary of common industry matches. Here is a slightly expanded explanation for each:

Material Type | Key Characteristics | Recommended Blade Type | Why This Blade Works |

Plastic (PP, PE, PET, Film) | Abrasive, can be soft/tough, often requires shearing and tearing. | Alloy Steel Blades (e.g., 42CrMo), Hook Type | The hook (or "claw") design grabs and stretches the material, providing a powerful shearing action. Alloy steel offers a good balance of hardness and toughness to resist abrasion. |

Metal (Aluminum, Steel Scrap) | Extremely hard and abrasive. Requires high cutting force and wear resistance. | D2 or SKD-11 Steel, Sawtooth or Straight | D2/SKD-11 are high-carbon, high-chromium steels known for exceptional wear resistance. Sawtooth blades are aggressive for thin metals, while straight blades are better for thick, dense scrap. |

Wood & Pallets | Fibrous, can contain nails/dirt (highly abrasive). Requires tearing and chopping. | Cr12MoV Steel, Sawtooth Blades | Cr12MoV is a durable tool steel that holds an edge well. The sawtooth geometry is ideal for grabbing and ripping apart wood fibers and can handle occasional contaminants. |

Tires & Rubber | Extremely tough and elastic, not abrasive. Requires tearing, not cutting. | High-Toughness Steel, Hook or Claw Type | The priority is toughness to avoid chipping. A sharp, hooked blade is designed to "bite" and tear the rubber, preventing it from simply bouncing away. |

E-Waste (WEEE) | A mixed and unpredictable stream (plastic, wires, PCBs, some metals). | High-Hardness Tool Steel, Sawtooth | This application demands versatility and extreme wear resistance to handle abrasive circuit boards and occasional metal parts. Sawtooth blades manage the variety effectively. |

2. Key Factors Beyond Material Type

While material is the primary driver, several other factors are crucial for optimal selection:

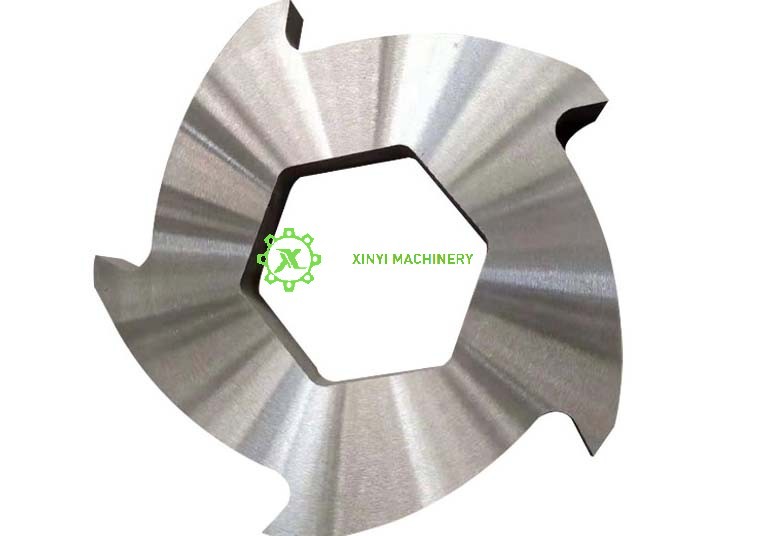

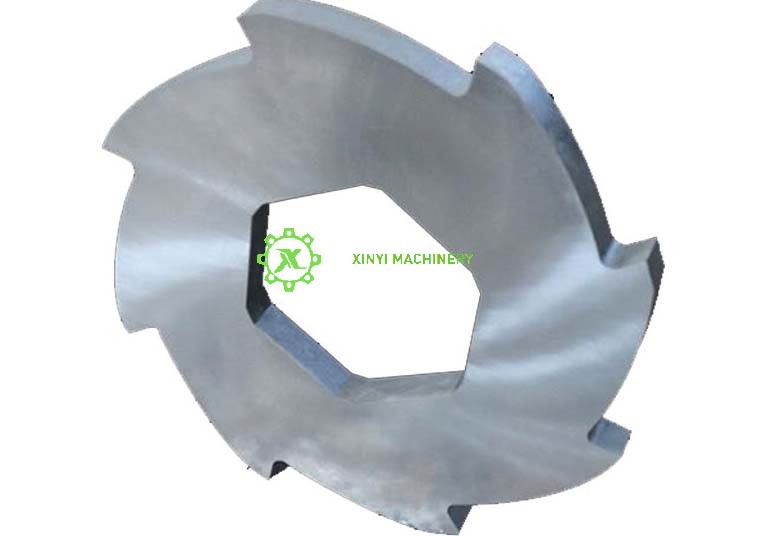

· Blade Geometry (Hook, Straight, Sawtooth): This determines the cutting action.

o Hook/Claw: Best for tearing and shearing flexible materials (plastic, rubber, paper).

o Sawtooth: Best for aggressive grabbing and ripping of fibrous materials (wood, carpet, e-waste).

o Straight: Best for precise cutting and chopping of brittle materials or thin metals.

· Hardness (HRC): Measured on the Rockwell C scale. Higher hardness (e.g., 58-62 HRC) provides better wear resistance but can be more brittle. Softer blades (e.g., 45-50 HRC) are tougher but wear out faster. The key is finding the perfect balance for your material.

· Steel Grade & Quality: The chemical composition of the steel dictates its core properties.

o D2 (SKD-11): Excellent wear resistance, moderate toughness.

o 42CrMo: High strength and good toughness, excellent for shock load.

o H13: Excellent thermal resistance and toughness, often used for hot-shredding applications.

· Maintenance & Service Life: Consider the total cost of ownership. A higher-quality, more expensive blade that lasts twice as long between sharpenings is often far more economical than a cheaper blade that requires frequent replacement and causes more downtime.

3. Why Choose a Specialist Manufacturer like XINYI MACHINERY?

As a leading manufacturer and factory supplier in China, XINYI MACHINERY provides significant advantages for your blade sourcing:

· Expert Application Matching: They can provide expert consultation beyond basic charts, offering tailored recommendations for your specific material mix and machine model.

· High-Quality Material & Heat Treatment: They control the entire manufacturing process, ensuring the use of genuine steel grades and precise heat treatment to achieve the optimal balance of hardness and toughness.

· Precision Engineering: Blades are machined to exact tolerances, ensuring perfect fitment, balanced rotation, and consistent performance in your shredder.

· Cost-Effectiveness: As a direct factory supplier, they offer competitive pricing without sacrificing quality, providing excellent value.

· Complete Range: They supply not just blades but also the entire shredder, crusher, and plastic crusher units, meaning they understand how all components work together as a system.

Conclusion:

Proper blade selection is not a one-time task but an ongoing process of optimization. By starting with the material-based guidelines and consulting with an experienced manufacturer like XINYI MACHINERY, you can ensure you select the right blades to maximize your shredding efficiency, reduce operating costs, and achieve your desired output quality.