What Is Ideal Hardness and Sharpness for the blades of Plastic Crusher/Plastic Shredder?

Expanded Explanation of Hardness and Sharpness

1. Ideal Hardness (HRC 55-65): The Trade-Off

This range represents the optimal compromise between two key properties:

Wear Resistance (Hardness): A harder blade maintains its edge longer when cutting abrasive materials.

Toughness (Resistance to Chipping): A tougher blade can withstand impact and shock without cracking or breaking.

Below ~HRC 55: The blade is too soft. It will lose its edge quickly, deform under load, and require frequent sharpening, increasing downtime and cost.

Above ~HRC 65: The blade becomes brittle. The high-impact forces in a shredder will cause the cutting edge to chip and fracture, rendering it useless.

Choosing within the range:

HRC 55-60: Leans towards toughness. Ideal for applications involving hard, brittle plastics or potential contamination (e.g., metals accidentally entering the hopper).

HRC 60-65: Leans towards wear resistance. Best for clean, highly abrasive materials or soft plastics where consistent, sharp cutting is needed and impact risk is lower.

2. Ideal Sharpness (Edge Geometry): It's About the Angle

sharpness is not one-size-fits-all. It refers to the edge angle or geometry.

For Soft Plastics (LDPE, PP, Film):

Require: A sharp, acute angle (e.g., 30°-45° included angle).

Why: These materials are ductile and tend to tear or stretch. A sharp, slicing edge creates a clean cut with minimal friction, preventing heat buildup and plastic from melting and gumming up the machine.

For Hard Plastics (PVC, PET, ABS):

Require: A strong, obtuse angle (e.g., 45°-60° included angle).

Why: These materials are brittle and fail by cracking. A more robust, blunter edge is less prone to micro-chipping and rolling over on impact, vastly improving edge retention and durability.

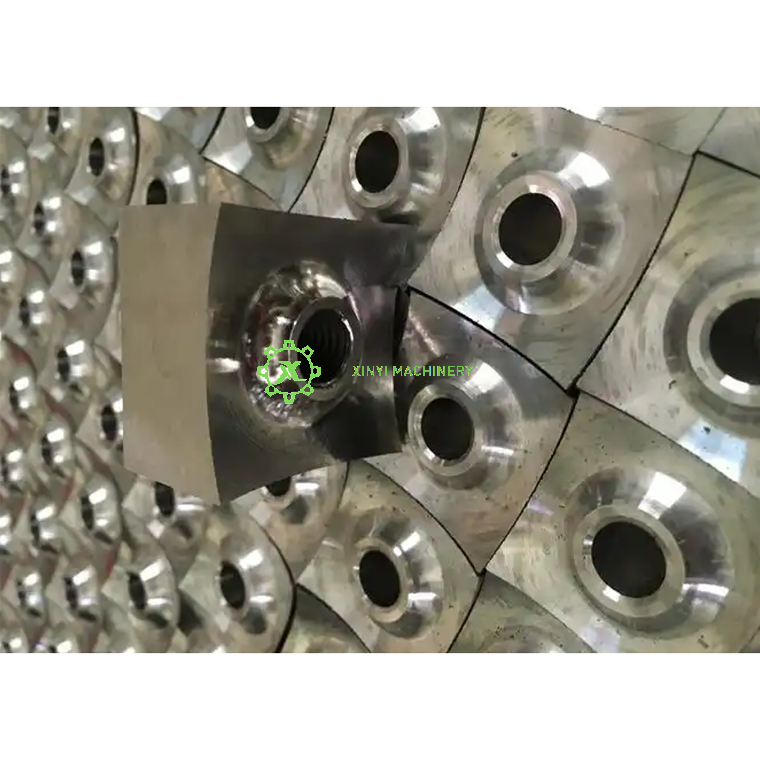

The Role of a Manufacturer Like XINYI MACHINERY

A leading manufacturer doesn't just supply a generic blade. They provide engineered solutions based on these principles:

Material Selection: They use the appropriate tool steel (e.g., D2, H13, 6CrW2Si) or tungsten carbide for each application, heat-treating it to the precise hardness required.

Precision Grinding: They grind the blades to the exact edge geometry optimal for the customer's specific material, whether it's a sharp angle for film or a robust angle for pipes.

Customization: They can design blades for specific machine models (e.g., granulators, wood shredders, PET crushers) and applications (e.g., PP pipe crushers), ensuring perfect fit and performance.

Expert Advice: They can provide crucial guidance on maintenance, optimal operation, and sharpening schedules to maximize blade life.

Conclusion:

For optimal performance and longevity, blade selection must be a calculated decision based on the material type. Partnering with an experienced manufacturer like XINYI MACHINERY ensures you get blades that are not just hard and sharp, but are correctly hard and correctly sharpened for your unique operational needs.