Starting a plastic recycling business with a phased, low-investment approach is smart and achievable. Here's a step-by-step plan based on your idea, minimizing initial risk:

Core Principle: Start Small, Focus on Profitability, Reinvest to Grow

Phase 1: Planning & Research (Critical Before Spending!)

o Market Research:

o Local Waste Stream: What types of plastic are thrown away most? (e.g., PET bottles, HDPE containers, LDPE film). Focus on abundant, easy-to-process types.

o Suppliers: Where will you get plastic? (Waste pickers? Small collection centers? Businesses? Municipal contracts?).

o Buyers: Who buys recycled plastic flakes/pellets? (Local manufacturers? Exporters? Brokers?). Understand their quality requirements and prices.

o Competition: Who else is recycling locally? What do they do? What gaps exist?

o Regulations: What licenses, permits, zoning, and environmental regulations apply? (This is CRITICAL - don't skip!).

o Business Plan:

o Define your niche (e.g., PET bottles, HDPE jerrycans).

o Calculate startup costs (basic equipment, rent, utilities, initial raw material purchase).

o Project operating costs (labor, power, water, transport, maintenance).

o Estimate revenue based on potential flake output and market prices.

o Determine your break-even point.

Phase 2: Starting Small - The "Flaking" Operation (Minimal Equipment)

· Goal: Produce clean, sorted plastic flakes (regrind) for sale.

· Core Process: Collection -> Sorting -> Crushing -> Washing (Manual/Basic) -> Drying (Sun/Manual) -> Flaking/Grinding -> Baling/Bagging.

· Minimal Essential Equipment:

o Plastic Crusher/Shredder: Breaks down bulkier items (bottles, containers).

o Blade grinding machine can help you to grind the blades of crushers automatically.

· Manual Labor is Key Initially:

o Sorting: Done meticulously by hand. Remove caps, labels, non-target plastics, contaminants. Quality here determines final flake price.

o Pre-Washing: Can be done manually in tanks or drums with water (detergent optional).

o Rinsing: Manual rinsing.

o Drying: Spread flakes on clean concrete or tarps in the sun; use manual labor to turn them. Simple centrifugal dryers (like modified spin dryers) can be a small upgrade.

o Bagging/Baling: Manual bagging or using a small manual baler.

· Location: Small yard or warehouse (ensure zoning allows industrial activity, drainage, storage).

· Operations:

o Source: Buy sorted bales of your target plastic from waste pickers or small aggregators.

o Process: Sort -> Crush -> (Manual Wash/Rinse) -> (Sun Dry) -> Grind -> (Final Sun Dry if needed) -> Bag/Bale.

o Sell: Target buyers needing clean flakes (e.g., local polyester fiber producers for PET, pipe manufacturers for HDPE).

Phase 3: Reinvest & Scale - Adding Capability & Quality (Your "Next Stage")

· Goal: Increase volume, improve flake quality (less contamination, moisture), process more plastic types, command higher prices.

· Reinvest Profits Into:

o Washing Line:

§ Wash Tank(s): For more effective label/contaminant removal.

§ Friction Washer: Scrubs labels and dirt off flakes.

§ Screw Conveyors: Move wet material between washing stages efficiently.

o Dewatering:

§ Centrifugal Dryer (Dewatering Machine): Removes most surface water mechanically, drastically reducing sun-drying time/space needed. This is often the first major upgrade after grinding.

o Improved Drying:

§ Air Conveying System: Moves dewatered flakes while exposing them to air flow.

§ Storage Silos with Air Flow: For final moisture balancing.

o Optional: Agglomerator: Compacts soft plastics (like film/LDPE) into denser pellets for easier handling before final granulation.

· Process Streamlining:

o Semi-Automatic Sorting: Maybe a simple conveyor belt for manual sorters.

o Material Handling: More conveyors to reduce manual lifting.

o Quality Control: Implement simple lab tests (moisture content, intrinsic viscosity for PET).

· Operations:

o Handle larger volumes.

o Process slightly more complex/mixed bales (still need good pre-sorting).

o Produce higher-value, more consistent flakes meeting stricter buyer specs.

o Explore new buyer markets.

Phase 4: Mature Plant - Pelletizing & Expansion

· Goal: Produce premium recycled plastic pellets, diversify feedstock, become a major supplier.

· Major Investment:

o Extrusion Line: The heart of pelletizing.

§ Extruder: Melts clean flakes.

§ Melt Filtration: Removes microscopic contaminants (essential for high-quality pellets - screen changers).

§ Pelletizing Die & Cutter: Forms and cuts the molten plastic into pellets.

§ Water Bath/Cooling: Cools pellets.

§ Centrifugal Dryer: Dries pellets.

o Advanced Sorting: Near-Infrared (NIR) sorters for high-purity streams.

o Dust Control & Ventilation: Improved working environment.

o Larger Space & Utilities: Significant power and water requirements.

· Operations:

o Process diverse plastic streams.

o Produce high-quality pellets meeting virgin plastic replacement specs.

o Target high-value markets (food-contact approved? automotive? requires extensive testing/certification).

Key Considerations Throughout Your Journey:

1. Plastic Types: Master one or two types first (PP& HDPE are often easiest). Each type has different processes and markets.

2. Quality is King: Contaminated or poorly processed material has little value. Invest in sorting and cleaning.

3. Input Supply: Securing consistent, affordable feedstock is critical. Build relationships with suppliers.

4. Output Market: Know exactly who will buy your product before you produce it. Lock in off-take agreements if possible.

5. Location: Proximity to suppliers/buyers reduces transport costs. Ensure utilities (3-phase power!), drainage, zoning.

6. Regulations: Never neglect permits (environmental, business, operational, waste handling), safety standards, and labor laws.

7. Operating Costs: Power, water, labor, maintenance, transport are significant. Track meticulously.

8. Safety: Plastic dust is flammable. Moving machinery is dangerous. Provide PPE (gloves, masks, goggles, ear protection) and training.

9. Networking: Join recycling associations, connect with other recyclers, attend trade shows.

10. Be Patient & Adaptable: Building takes time. Markets fluctuate. Be ready to adapt your processes or product focus.

Summary of Your Phased Equipment Plan:

· Start: Crusher + Manual Labor (Sorting, Washing, Drying) + Basic Space.

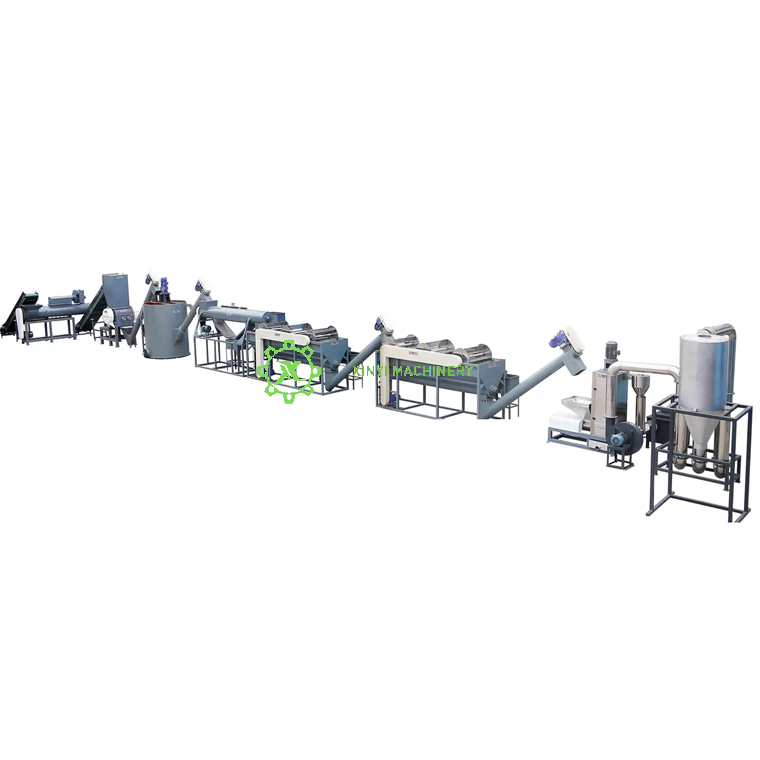

· Reinvest (Stage 1): Add Hot Wash Tank, Friction Washer, Screw Conveyors, Centrifugal Dryer (Dewatering).

· Reinvest (Stage 2): Add Air Conveying/Drying Silos, maybe Agglomerator.

· Mature: Add Extrusion Line (Extruder, Filtration, Pelletizer, Cooler, Dryer) + Advanced Sorting.

By starting small with core processing (crushing/grinding), focusing intensely on quality sorting and manual cleaning, and reinvesting profits strategically into washing and dewatering first, you significantly reduce your initial financial risk and build a solid foundation for sustainable growth. Good luck!