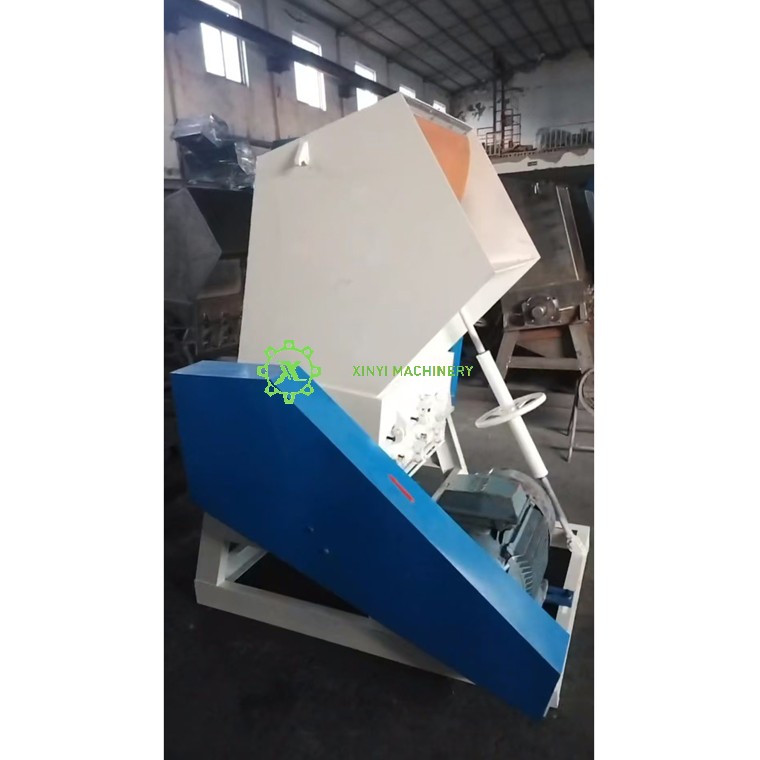

Operating an industrial-grade plastic bottle crusher is significantly more complex than using a home/office model, but it's not inherently "difficult" for trained personnel. Success depends heavily on proper training, adherence to safety protocols, and maintenance discipline. Here's a breakdown:

🔧 Key Factors Impacting Difficulty (Industrial Context):

Safety Complexity:

High-pressure hydraulics, heavy moving parts, and electrical systems pose serious risks (crush injuries, entanglement, electrical hazards).

Mandatory training covers lockout/tagout (LOTO), emergency stops, PPE (gloves, goggles, hearing protection), and safe clearance zones.

→ Without training: Extremely hazardous.Technical Operation:

Involves control panels (PLC/HMI interfaces), conveyor systems, hydraulic pressure settings, and jam-clearing procedures.

Requires understanding startup/shutdown sequences, material feed rates, and troubleshooting error codes.

→ Basic operation (pressing start) is simple; optimizing performance is technical.Pre-Processing Requirements:

Bottles must be pre-sorted (by plastic type, e.g., PET-only), de-capped, and free of contaminants (liquids, metals, labels in excess).

Industrial crushers are less forgiving of non-conforming materials → causes jams or damage.

Maintenance Demands:

Daily lubrication, weekly inspections of blades/hydraulics, monthly filter changes, and annual system overhauls.

Requires technical skills (e.g., diagnosing hydraulic leaks, replacing wear parts).

Throughput & Efficiency:

Optimizing crusher speed, feed consistency, and output volume requires experience. Underloading/overloading reduces efficiency.

✅ What Makes It Manageable:

Structured Training: Manufacturers provide detailed operation & safety training (typically 1-3 days). Certified operators handle routine tasks confidently.

Standardized Procedures: Checklists for startup, operation, shutdown, and jam clearance reduce errors.

Automation: Many industrial crushers integrate auto-feed conveyors, sensors, and self-diagnostics.

Support: Technical manuals, service contracts, and hotline support mitigate challenges.

⚠️ Attention Items (Critical Pre-Use Requirements):

Read ALL Manuals: Operator’s guide, safety manual, and maintenance schedule.

Inspect Before Use: Check hydraulic lines, blades, guards, and emergency stops.

Wear PPE: Cut-resistant gloves, safety glasses, steel-toe boots, hearing protection.

Pre-Process Bottles: Remove caps/lids, drain liquids, ensure PET-only feed.

Know Emergency Protocols: Location of E-stops, fire extinguishers, and first-aid kits.

Never Bypass Safeguards: Do not disable safety interlocks or guards.

📊 Difficulty Summary:

| Aspect | Home Crusher | Industrial Crusher |

|---|---|---|

| Operation | Stomp/Press button | Control panel + settings |

| Safety Risk | Low | High (requires strict protocols) |

| Training Needed | None | Mandatory (1-3 days) |

| Maintenance | Wipe clean | Scheduled technical upkeep |

| Pre-Processing | Decap 1 bottle | Decap + sort bulk feed |

💎 Conclusion:

For trained professionals following protocols, operating an industrial crusher is manageable and efficient. However:

➠ Without training/attention items: It’s hazardous and prone to breakdowns.

➠ Mastery requires experience (e.g., diagnosing jams, optimizing throughput).

Always prioritize manufacturer training and never skip pre-operational checks. When used correctly, industrial crushers are powerful assets for recycling operations – but respect the machinery’s power and complexity.