Turning PET water bottles into pellets is a multi-step industrial recycling process (mechanical recycling) that transforms waste bottles into reusable raw material. Here's a breakdown of the key stages:

The Goal: Convert sorted, clean PET bottles into uniform PET flakes → Melt → Extrude → Cut → Cool into pellets ("PET pellets").

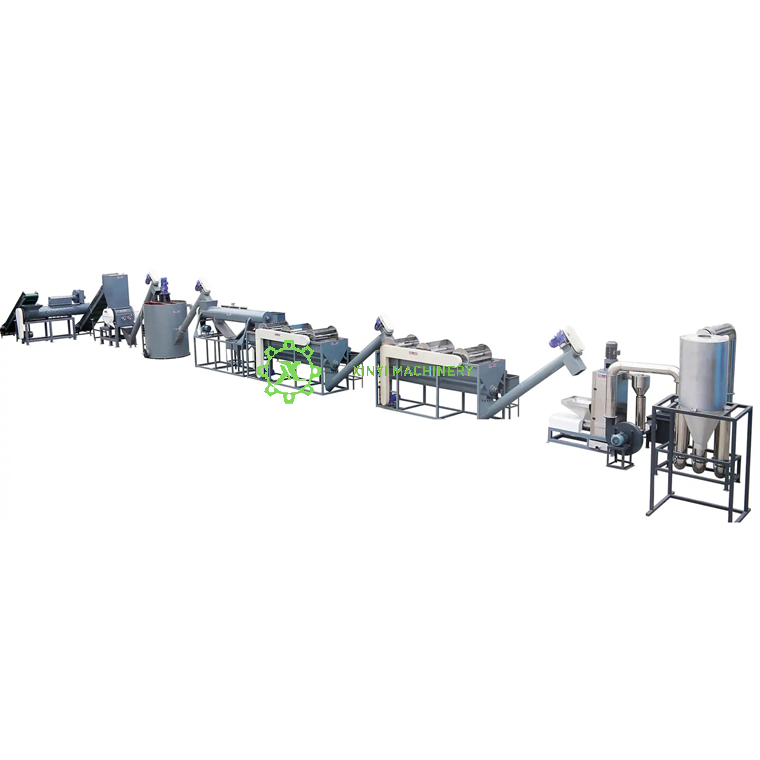

Key Process Steps:

Collection & Sorting:

By Polymer Type: PET must be separated from HDPE, PP, PVC (contaminants), metals, glass, etc. (Done via NIR sensors, optical sorters, air jets, magnets, eddy currents).

By Color: Clear/light blue PET is highest value. Green/other colors are separated for different streams.

Removal of Non-PET Components: Caps (usually PP or HDPE), labels (PP, PE, paper), glue, residue.

Collection: PET bottles are gathered through municipal recycling programs, deposit systems, or commercial collection.

Sorting (Crucial!):

Pre-Washing (Optional but common):

Removes loose dirt, sand, liquids, and some initial labels/glue using water and mild detergents.

Size Reduction (Grinding):

Bottles are fed into powerful granulators or shredders.

Rotating blades cut them into small, uniform pieces called "PET flakes" (typically 6-20mm).

Output: Dirty, mixed-color flakes with labels, caps, and neck rings still partially attached.

Washing & Cleaning (Multi-Stage): This is critical for food-grade rPET.

Flakes are fed into a water tank with controlled density/speed.

PET sinks (density ~1.38 g/cm³).

Lighter contaminants float (PP caps, PE labels, foils).

Heavier contaminants sink faster (metals, sand - removed separately).

Dissolves glues and adhesives.

Loosens and separates labels.

Decontaminates the surface.

Hot Caustic Wash: Flakes are agitated in hot water with caustic soda (NaOH). This:

Friction Washers: Mechanical scrubbing removes stubborn contaminants.

Rinsing: Multiple stages with clean water remove caustic residue and dissolved contaminants.

Sink-Float Separation (Hydrocyclone):

Dewatering (Mechanical Water Removal):

Wet flakes exit the wash line.

A Centrifugal Dewatering Machine (spin dryer) spins flakes at high speed, using centrifugal force to remove >90% of the surface water. (This answers your previous question!)

Output: Damp flakes (still 3-8% moisture).

Thermal Drying:

Essential for extrusion! Residual moisture causes PET to hydrolyze (degrade) during melting, reducing quality.

Flakes are fed into a Hot Air Dryer (e.g., hopper dryer, desiccant dryer).

Heated, dry air circulates, reducing moisture content to <0.02% (typically 50-180°C, depending on dryer type and residence time).

Extrusion & Filtration (Melting & Cleaning):

Molten PET is forced through fine screen packs (e.g., 150-250 microns) inside a screen changer.

This removes tiny solid contaminants (dust, microplastics, charred bits, undissolved glue flecks).

Screens are changed automatically as they clog.

Feeding: Dried flakes are fed into an Extruder.

Melting: A rotating screw conveys flakes through heated barrels. Friction and barrel heaters melt the PET into a viscous liquid (~260-290°C).

Filtration (Critical for Quality):

Degassing (Optional but common): Vacuum ports along the barrel remove trapped air and volatile contaminants.

Pelletizing:

Molten PET is cut by knives directly at the die face underwater.

Water instantly cools and hardens the pellets.

Produces more spherical pellets, often preferred.

Molten PET forms strands.

Strands are pulled through a water bath for cooling/solidifying.

Solid strands enter a Strand Cutter (rotating knives) and are chopped into uniform pellets (typically 2-5mm).

The clean, molten PET exits the extruder through a die plate with multiple small holes.

Strand Pelletizing:

Underwater Pelletizing:

Cooling & Drying:

Pellets exit the cutter warm and wet.

They pass through Cooling/Centrifugal Dryers to remove surface water and cool them completely to handling temperature.

Quality Control & Packaging:

Intrinsic Viscosity (IV): Measures molecular weight/degradation.

Moisture Content: Must be very low (<0.02%).

Color: Consistency.

Contamination Levels: Visual/microscopic inspection, ash content.

Melting Point/Crystallinity.

Pellets are tested for:

Packaging: Clean, dry pellets are packaged in big bags (FIBCs), boxes, or silos for shipment to manufacturers.

Key Considerations & Challenges:

Feedstock Quality: Contamination (PVC, oils, other plastics) ruins batches. Sorting is paramount.

Moisture Control: Drying before extrusion is non-negotiable for PET.

Thermal Degradation: Excessive heat or time in the melt causes IV drop. Careful temperature control is vital.

Filtration: Determines the purity and quality of the final pellets (esp. for food contact).

Food-Grade vs. Non-Food-Grade: Achieving food-grade rPET (e.g., for new bottles) requires stricter sorting, cleaning, decontamination (e.g., "super-clean" recycling processes), and regulatory approval.

Energy Intensity: The process requires significant energy (washing, drying, extrusion).

End Uses for rPET Pellets:

New PET Bottles & Food Containers (Requires food-grade approval)

Polyester Staple Fiber (PSF) for clothing, carpets, stuffing (pillows, toys)

PET Sheet for thermoformed packaging (blisters, clamshells)

Strapping for securing pallets

Automotive Parts (carpet, trunk liners, seat fabrics)

Construction Materials (insulation, geotextiles)

This process closes the loop on PET plastic, conserving resources and reducing landfill waste!