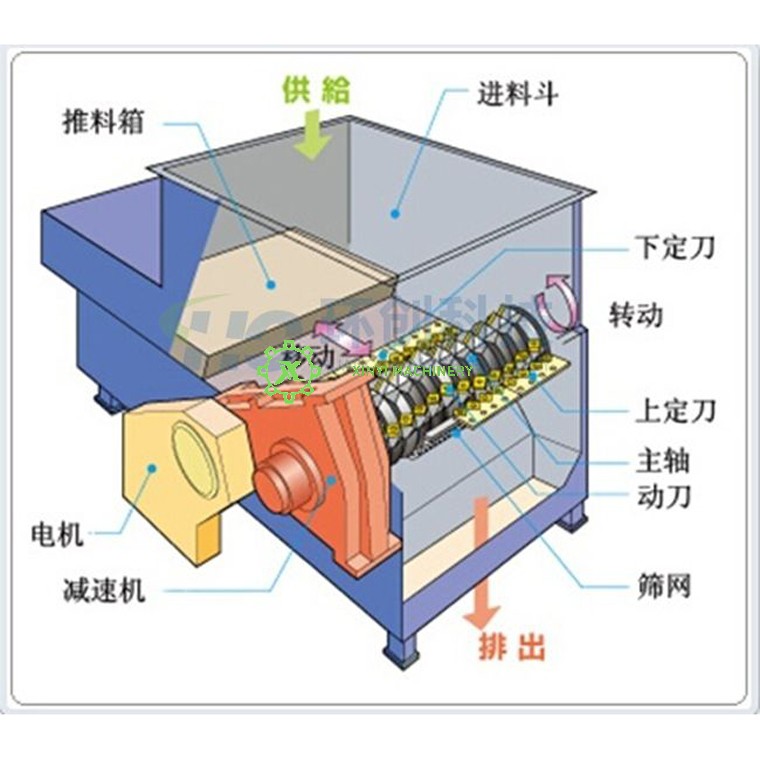

Shredder blade for shredder one of the most important accessories, shredder blade good or bad directly affects the cycle of mechanical processing of waste materials, in accordance with the classification of shredder, shredder blade is divided into single-axis shredder blade and multi-axis shredder blade. As a shredder on an important crushing operation with the knife. According to the shredder structure classification, shredder blades can be divided into single-axis shredder blades, multi-axis shredder blades (including double-axis shredder blades and four-axis shredder blades).

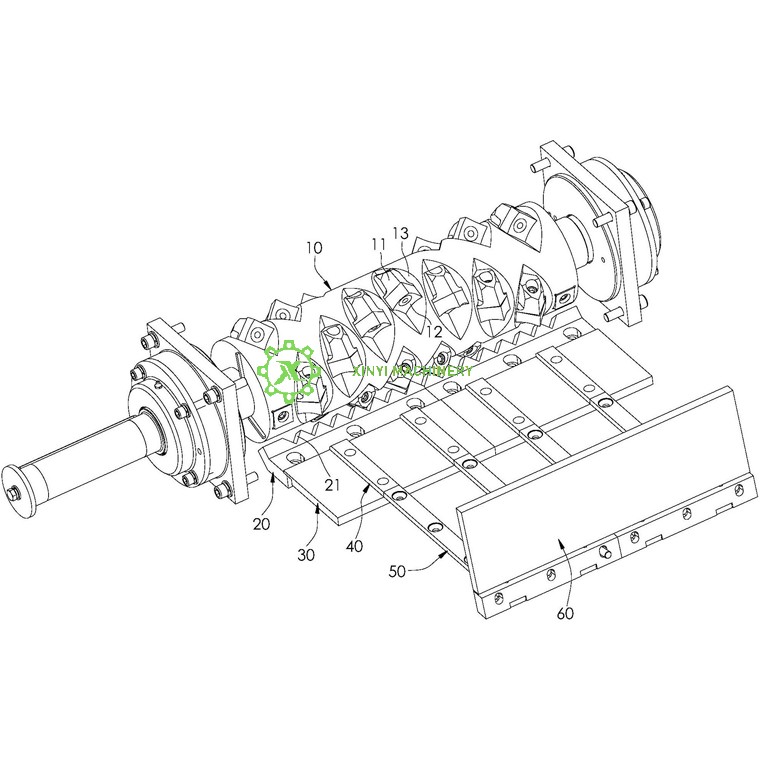

Single-shaft shredder blade, as the name suggests, is installed on the shaft of the single-shaft shredder, also known as the moving knife. The shape of the square, the knife mouth on all sides of the curvature, the center of the tapping hole, the knife mouth to the center hole part of the inward concave, with the knife frame on the fixed knife to use. General selection of SKD11, D2, DC53 and other materials.

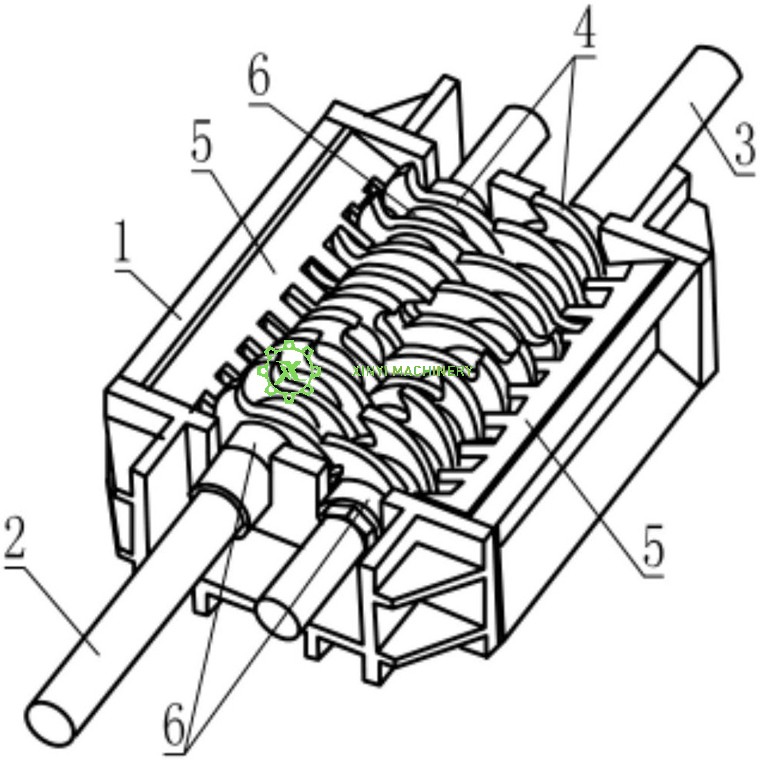

Multi-shaft shredder blade for claw knife, according to the design of each company, installed in the two-axis or four-axis shredder, generally can be divided into 3 claw shredder blade, 5 claw shredder knife, 8 claw shredder blade, etc., used for crushing, tearing and extrusion to achieve the size of the material to reduce the size of the shredder blades are widely used in waste plastics, waste rubber, wood and other large volume of waste material crushing. Generally use 55SiCr, H13, D2 and other materials.

XINYI MACHINERY is a China leading Manufacturer of all kinds of shredder blades and shredders.

Conclusion: There is No Single "Best" Material

The best material is the one perfectly matched to the shredding application.

For wear resistance against abrasive materials (plastics, wood): 9CrSi, D2 ,SKD11 is the standard.

For impact resistance against tough materials (metals, tires): 55SiCr and H13 are the champions.

As a leading manufacturer, XINYI MACHINERY's expertise lies not just in making blades, but in recommending the right material and heat treatment combination to maximize your customers' productivity and minimize their downtime for blade changes. Offering a range of options from 9CrSi to SKD11 and specialized 55SiCr will cover the vast majority of industrial shredding needs.