It is not recommended and likely ineffective, or even dangerous, to use a standard plastic bottle crusher to crush solid plastic blocks.

Here’s a detailed breakdown of why:

1. Fundamental Design Differences

A plastic bottle crusher and a machine designed for plastic blocks are engineered for completely different types of material and force.

Feature | Plastic Bottle Crusher | Plastic Block Crusher/Shredder |

Primary Force | Compaction | Shearing & Crushing |

Target Material | Hollow, thin-walled, flexible (PET/HDPE bottles) | Solid, dense, rigid (purgings, lumps, thick sheets) |

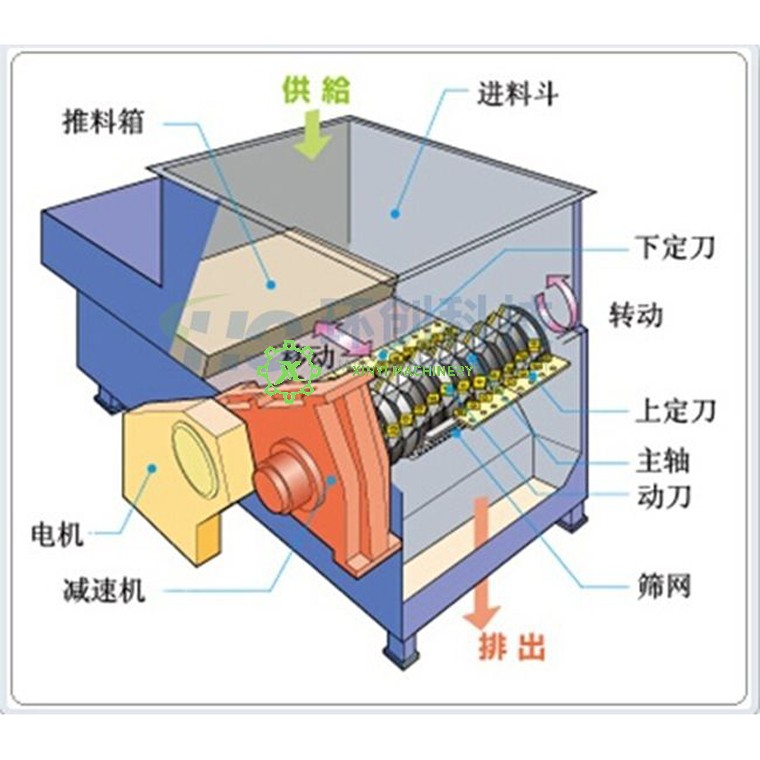

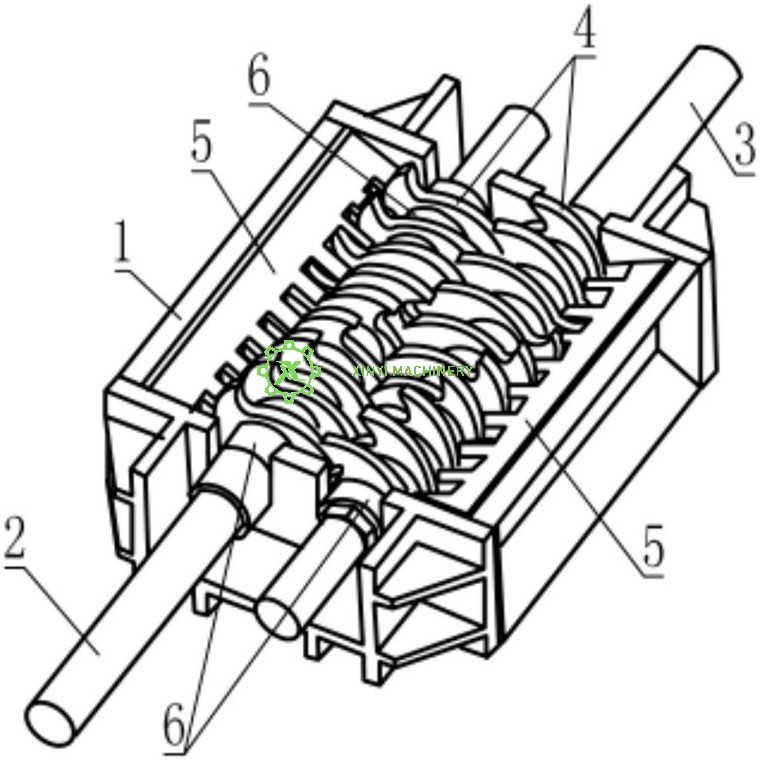

Mechanism | Ram crushes against a solid wall or plate. | Interlocking rotary blades (shredder) or a powerful, slow-speed ram with a large mechanical advantage (granulator). |

Power & Torque | Lower power; designed to collapse air pockets. | Very high power and torque; designed to fracture solid plastic. |

End Result | Flattened bale for volume reduction. | Small chips or flakes (aka "regrind" or "granules") for recycling. |

2. Why a Bottle Crusher Will Fail with Plastic Blocks

Insufficient Force: The hydraulic ram or mechanical press in a bottle crusher is designed to overcome the structural rigidity of a hollow bottle. A solid plastic block might have 10-100 times more mass and structural integrity. The crusher's motor and frame are not built to generate or withstand the force needed to break it.

Wrong Type of Force: Crushers compact; they don't cut. A solid block will simply resist being compacted. At best, it might get slightly dented. At worst, you will...

Risk of Damage: You risk stalling, burning out the motor, bending the ram, or cracking the welds on the machine's frame. This can lead to costly repairs.

Safety Hazard: Applying extreme pressure to a solid block in a machine not designed for it can be dangerous. The block could shatter and eject fragments, or the machine itself could fail catastrophically.

3. What You Should Use Instead for Plastic Blocks

For reducing solid plastic blocks (which are often production waste like sprues, purgings, or lumps), you need an industrial shredder or a heavy-duty plastic crusher.

Single-Shaft Shredder: These are the workhorses for pre-breaking large, bulky, and solid materials. They use a powerful, slow-turning rotor with hooked blades that grab, tear, and shear the material into smaller, manageable pieces.

Heavy-Duty Plastic Crusher: For smaller blocks or to achieve a finer granules, a heavy-duty plastic crusher with a "scissor-cut" action is used. These have higher RPMs than shredders and are designed for continuous size reduction.

Two-Shaft or Four-Shaft Shredder: These use two or four interlocking shafts with blades to provide tremendous shearing force, perfect for tearing apart the toughest and densest materials.

These machines are built with:

High-Torque, Low-Speed motors to generate massive cutting force.

Hardened Steel Blades that can withstand the abrasion and impact of solid plastic.

Massive Frames and Bearings to absorb the extreme stresses involved.

Conclusion:

Think of it like this: you could try to hammer a nail with a shoe, but it's inefficient, won't work well, and you'll ruin the shoe. A hammer is the right tool for that job.

Similarly, a bottle crusher is for compaction, and a shredder/granulator is for size reduction. Using the wrong equipment will be ineffective, risk damaging your machine, and could create a safety hazard.

XINYI MACHINERY is a China leading manufacturer of all kinds of plastic bottles crushers, heavy-duty crushers, industrial crushers, industrial shredders, single-shaft shredders, double-shaft shredders, etc.